Getting your lifting equipment from overseas manufacturers? Not a problem. We can also help with the review, analysis and certification of equipment imported to Australia.

Whether you're bringing in major machinery or lifting accessories for a range of industries, we can help ensure it's safe and reliable for Australia's demanding standards.

Importing your lifting equipment? We can help with that, too.

We specialise in certifying and designing lifting equipment.

From concept through certification, our engineers design and verify lifting devices that meet the required standards and real-world demands.

We combine practical manufacturing know-how with advanced analysis to optimise strength, weight, and usability. We can then work with you to meet your certification and compliance requirements.

We work as an extension of your team on projects large and small: one-off spreader bars, jib cranes, forklift attachments, engine hoists, lifting frames, davits, rigging components, and more.

Industries we support include: construction, manufacturing, mining, agriculture, transport and trucking, rail, warehousing, logistics, marine, recycling and waste management, energy, defence, local government, infrastructure maintenance, forestry, and events/entertainment rigging.

Choosing Quantech Design means faster approvals, fewer redesigns, and equipment that performs as specified: safely, efficiently, and compliantly.

Our process for precise equipment design.

Define the job and scope.

When we take on a design and certification job, we consider:

-

Rated capacity, load geometry, centre of gravity, lift points, lift path, headroom, and handling/assembly constraints.

-

Duty cycle and environment: frequency of use, corrosion, temperature, contamination, outdoor vs indoor.

Engineering the solution.

When we enter the engineering phase of the project, we:

-

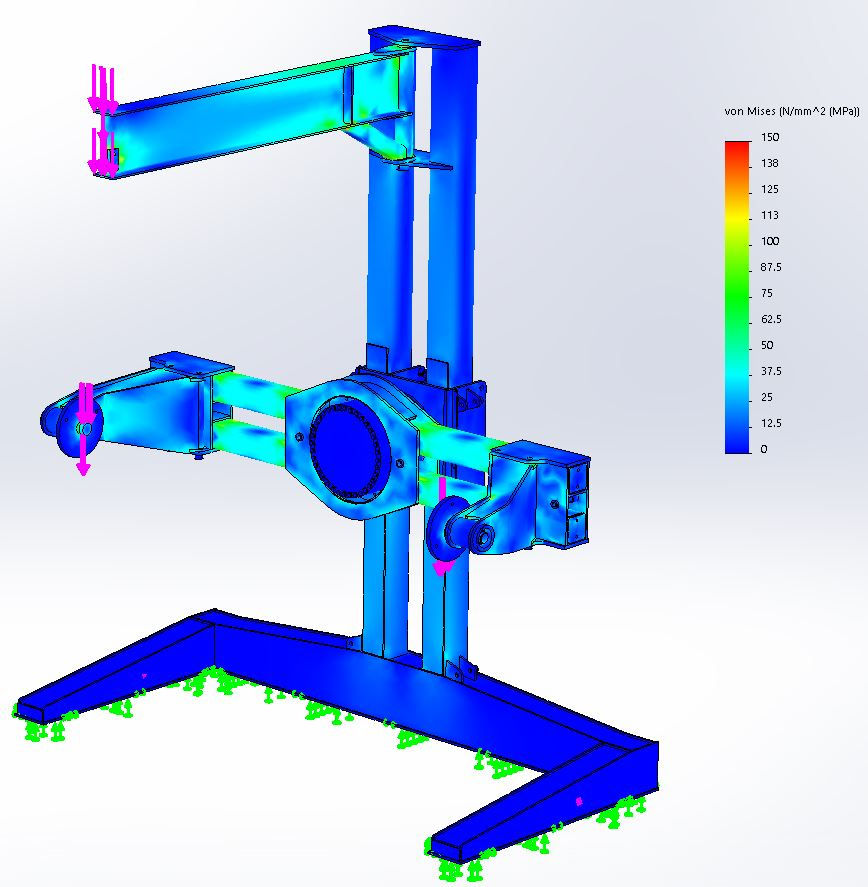

Establish load paths and safety factors; check bending, shear, buckling, deflection and stability.

-

Assess fatigue for repeated lifting.

-

Verify connections: weld sizes, bolt grades/preloads, pin/bush bearing stresses and clearances.

Fabrication consideration.

We'll consider all aspects of fabrication in our design process:

-

Refine your design to be stronger and lighter, and make manufacturing easier and more cost-effective.

-

Choose practical sections and welds for cost-effective manufacture and repeatability.

-

Consider compliance and certification requirements, wear and tear, and protective finishes.

Testing and certification.

We specialise in FEA analysis to test your lifting equipment design so you can be confident it will perform as it's intended.

We can also provide engineering analysis reports and validations to support certification and compliance requirements specific to your industry.